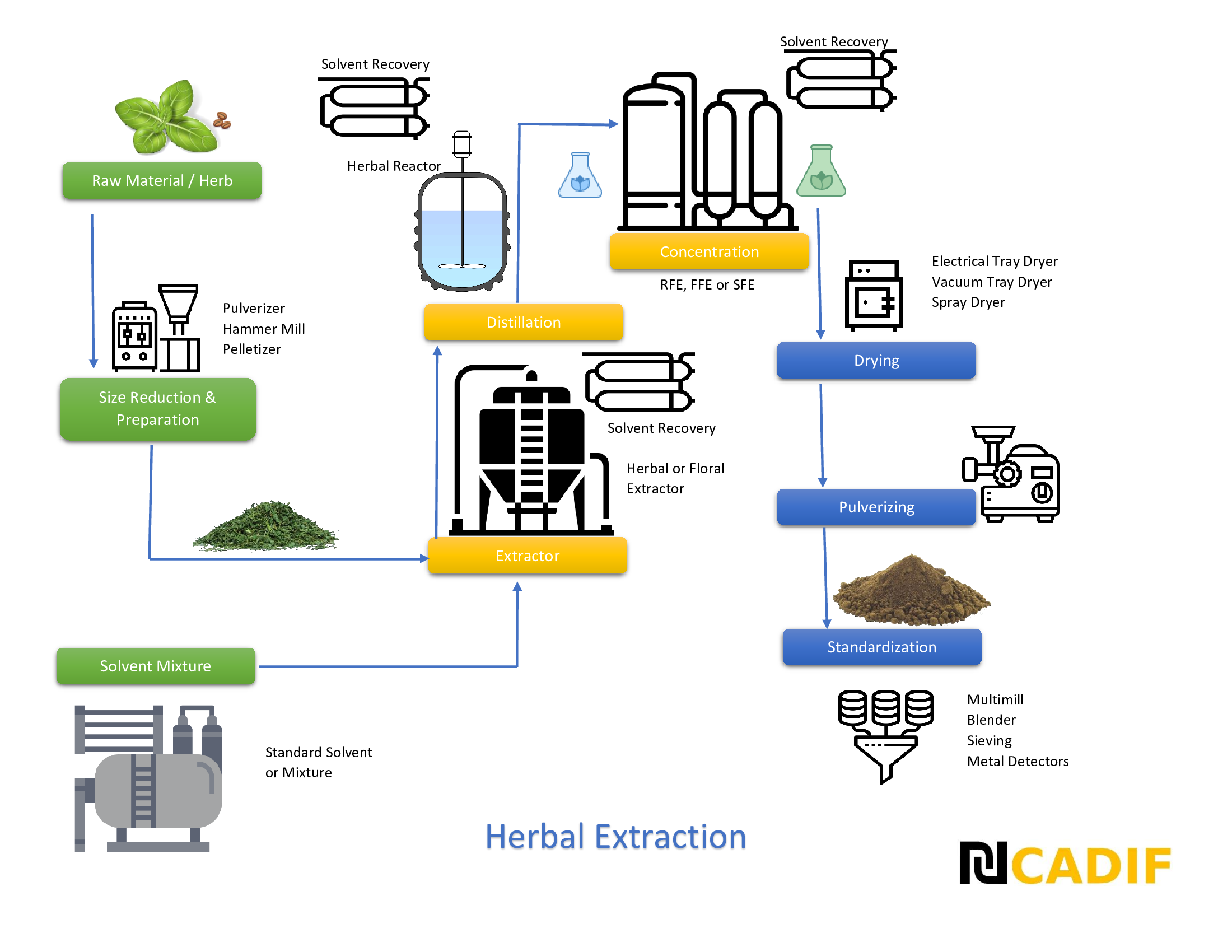

Essential oil distillation, Floral & Herb Extraction and Concentration.

Herbal extraction plant is a combined unit consisting of various set of equipment’s. It is suitable for the extraction, concentration, ointment collection, percolation, volatile oil extraction and alcohol recovery of heat sensitive materials.

The essential oil extraction plant generally include extractor, concentrator, receiver, condenser, cooler, pipes, valves, meters, water-oil separator, filter, vacuum pump, transfer pump, and so on.

Herbal Extraction Principle Process.

1. Herb (leaves, root, flower or seed) is sorted, sized as per the requirements.

2. The processed herb is then fed into extractor into which solvent/water is fed. Once the extractor is heated, the critical components from herb will dissolved into water or solvent.

3. After extraction, pump the extracted liquid into the concentrator, evaporate the water or solvent (like alcohol) which will be cooled by condenser and flow to receiver. The collected solvent can be reused.

4. The rich concentrate is then fed into reactors for further processing like adding additives, Ph Balancing etc. Based on the requirement of the particular product.

5. The product is then dried using any one of the drying process. (Electrical Dryer, Spray Dryer, Vacuum Tray Dryer etc.)

6. The dried product is then further processed and packed.